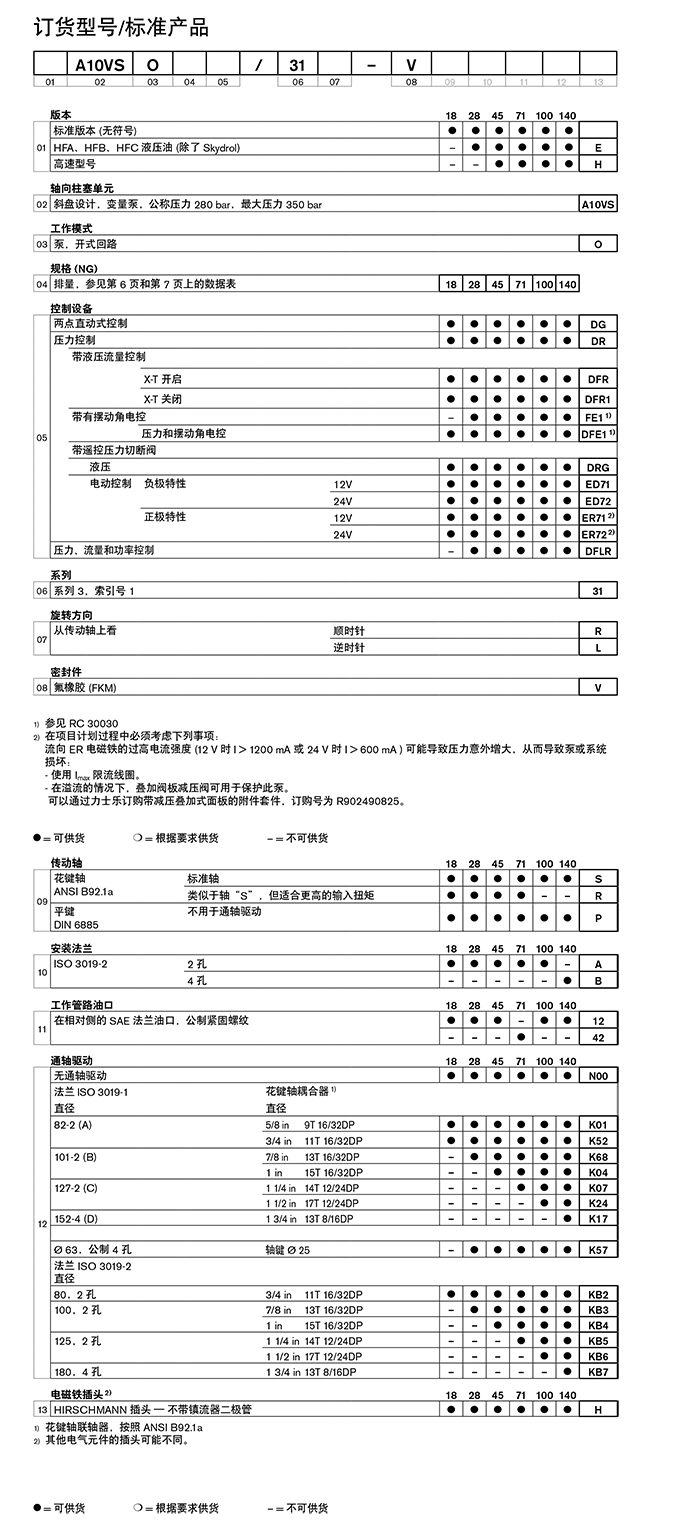

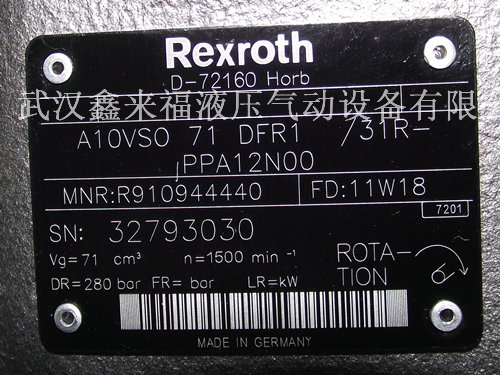

Rexroth A10VSO plunger pump

|

series

|

A10VSO series variable piston pump (31 series)

|

|

specification

|

28、45、71,、100,、140

|

|

|

Work pressure

|

Rated pressure: 28MPa, peak pressure: 35 MPa

|

|

|

|

characteristic

|

-Axial plunger variable pump with swash plate structure, used for hydrostatic transmission in open circuit.

-The flow rate is proportional to the transmission speed and displacement. -By adjusting the angle of the swash plate, a stepless change in flow can be achieved. -2 case drain ports. -Outstanding oil absorption characteristics. -Low noise level. -Long service life. -The axial and radial load capacity of the drive shaft. -Ideal power-to-weight ratio. -Various control ranges. -Short control time. -The pump has a through-shaft drive and can be equipped with gear pumps or axial piston pumps of the same specification or less, that is, 100% through-shaft drive.

|

safety instructions

-The A10VSO pump is designed for use in an open circuit.

-Project planning, assembly and commissioning of the axial piston unit must be carried out by qualified personnel.

-Before using the axial piston unit, please read the corresponding instruction manual completely.

-If necessary, please request these manuals from Bosch Rexroth.

-During and shortly after operation, the axial piston unit (especially the solenoid) may be at risk of causing burns. Appropriate safety measures (such as wearing protective clothing) should be taken.

-According to different working conditions (working pressure, oil temperature) of the axial piston unit, the characteristics may change.

-Working line oil port:

· The oil port and fixed thread are designed for the maximum specified pressure. The manufacturer of the machine or system must ensure that the safety factors of the connected components and pipelines meet the specified working conditions (pressure, flow, hydraulic oil, temperature).

· The working line ports and function ports are only designed for hydraulic lines.

-Pressure cut-off and pressure control do not provide overpressure protection. A separate relief valve is provided in the hydraulic system.

-The data and instructions contained herein must be followed.

-This product is not certified as a part that meets the requirements of the general machine safety concept of DIN EN ISO 13849.

-Use the following tightening torques:

· Connector:

Refer to the manufacturer's instructions for the tightening torque of the joints used.

· Mounting bolts: For mounting bolts that meet the ISO metric thread standard of DIN 13 and the thread standard of ASME B1.1, we recommend checking the tightening torque separately according to VDI 2230.

· The threaded hole of the axial plunger unit:

The maximum allowable tightening torque MG max is the maximum value for threaded holes and must not exceed this value.

· Locking screw:

For the metal locking screw provided with the axial plunger unit, a tightening torque MV is required.

|

|

|

|

|

|

|

|

|

|